Mining is one of the big contributors to the nation’s GDP in Zimbabwe. Morewear Manufacturing has products that are specific to three main sectors of the economy in Zimbabwe:

- The mining sector

- The agriculture sector

- The transport and energy sector

Under general engineering, products are of a general nature and are not restricted to any sector. In this post, i am going to dwell on products and services specifically for the mining sector that Morewear Manufacturing offers.

Leach Tanks For Mineral Extraction

Leaching is the process of a solute becoming detached or extracted from its carrier substance by way of a solvent.

Leaching is a naturally occurring process which scientists have adapted for a variety of applications with a variety of methods. Specific extraction methods depend on the soluble characteristics relative to the sorbent material such as concentration, distribution, nature, and size. Leaching can occur naturally seen from plant substances (inorganic and organic), solute leaching in soil, and in the decomposition of organic materials. Leaching can also be applied affectedly to enhance water quality and contaminant removal, as well as for disposal of hazardous waste products such as fly ash, or rare earth elements (REEs). Understanding leaching characteristics is important in preventing or encouraging the leaching process and preparing for it in the case where it is inevitable.

In an ideal leaching equilibrium stage, all the solute is dissolved by the solvent, leaving the carrier of the solute unchanged. The process of leaching however is not always ideal, and can be quite complex to understand and replicate, and often different methodologies will produce different results.

Leaching is widely used in extractive metallurgy where ore is treated with chemicals to convert the valuable metals within into soluble salts while impurity remain insoluble. These can then be washed out and processed to give the pure metal; the material left over is commonly referred to as tailings. Compared to pyrometallurgy leaching is easier to perform, requires less energy and is potentially much less harmful as no gaseous pollution occurs. Drawbacks of leaching include its lower efficiency and the often significant quantities of waste effluent and tailings produced, which are usually either highly acidic or alkali as well as toxic (e.g. bauxite tailings).

There are four types of leaching:

- Cyanide leaching (e.g. gold ore)

- Ammonia leaching (e.g. crushed ore)

- Alkali leaching (e.g. bauxite ore)

- Acid leaching (e.g. sulfide ore)

At Morewear Manufacturing, or engineering expertise assists the mining industry with setting up leach tanks and other apparatus that are involved in the extraction of minerals from ore. Zimbabwe is a mineral rich country with mineral types reaching over a hundred. Of the world’s most precious minerals which are argued to be 42 in number, Zimbabwe alone has 24 of those precious mineral types.

We have partnered before with Freda Rebecca Mine in Bindura, Zimbabwe and we designed, constructed and erected their leach tanks and other apparatus instrumental in the extraction of gold at the mine.

Leach Tanks At Freda Rebecca Mine (Bindura)

Another client that we have worked with is Suraj Mine in Mtawatawa. Our company designed, constructed as well as erected their leach tanks as well as other apparatus for mineral extraction at the mine.

Leach Tanks At Suraj Mine (Mtawatawa)

The other products that we design and manufacture as Morewear Manufacturing include rail wagons. This is specifically for the mining industry. We design and manufacture rail wagons from the ground up or repair and service those that has gone out of commission. We are backed up by a workshop that is well equipped for any kind of job. We service all rail rolling stock.

Rail wagons and rolling stock

Every mining operation develops a community. This is so as employees and their depended end up living at or around the mine so that they are closer to their workplaces. This leads to the development of an organized community. An organized community ends up requiring their refuse to be managed in a hygienic way. At this point, we chip in with a product for refuse collection in the form of skip bins. We modify any vehicle that may need to be mounted with a skip bin.

Skip Bins for Refuse Collection

Some of the products that the Zimbabwean mining sector may benefit are steel fuel tanks. Fuel supply is critical for any mining operation as vehicles and equipment run on fuel. This makes it a imperative for mining operations to have large capacity fuel storage facilities. We manufacture steel fuel tanks with different capacities which range from 20000litres to 50000litres. Our expertise span ground preparation for the installation of these fuel tanks, installing them as well as construction of fuel station sheds.

Our tanks can be above ground or underground and they are constructed according the industry specified standards. At this point it is important for us to point out that we are a member of the Engineering Association of Zimbabwe (EISAZ). Our work is top notch, safe and durable such that you will be delighted to deal with us for the second time.

Fuel Tanks and Fuel Tankers

fuel tank

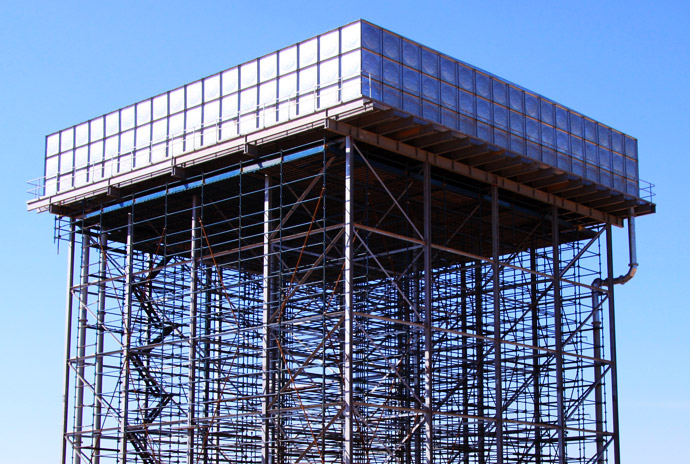

Mining operations may also need modular tanks for water storage as well as air receivers or pressure vessels for various mining activities. All these products are part of Morewear Manufacturing product catalogue.

Our products and services include many others that have not been mentioned individually. If you need anything closely related to any product listed in this article or any other non mining related products that we offer, kindly get in touch using any of the communication media that we have listed on our website. Feel free to browse through or web pages and we would be glad to receive any comments or requests from you.